Our team will assist you shortly.

Product Attributes

| Type | Description | |

|---|---|---|

| Category | ||

| Import Duty Classification | - | |

| Product Series Line | HXP | |

| IC Encapsulation Type | Tray | |

| Availability Status | Active | |

| Ohm Resistance Value | 100 mOhms | |

| Accuracy Tolerance Percentage | ±5% | |

| Wattage Power Level | 200W | |

| Material Blend | Thick Film | |

| Temp Drift Factor | ±500ppm/°C | |

| Ambient Temp Range | -55°C ~ 155°C | |

| Key Product Highlights | Non-Inductive | |

| Protective Enclosure Finish | Epoxy Coated | |

| Installation Mount Type | Flanges | |

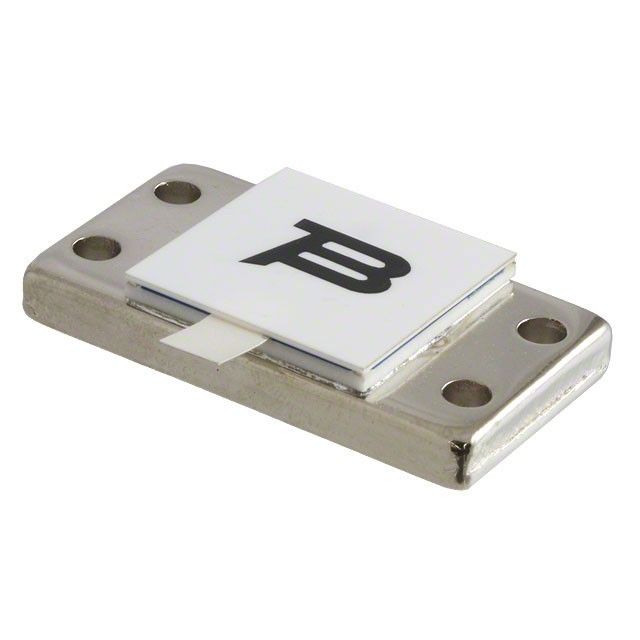

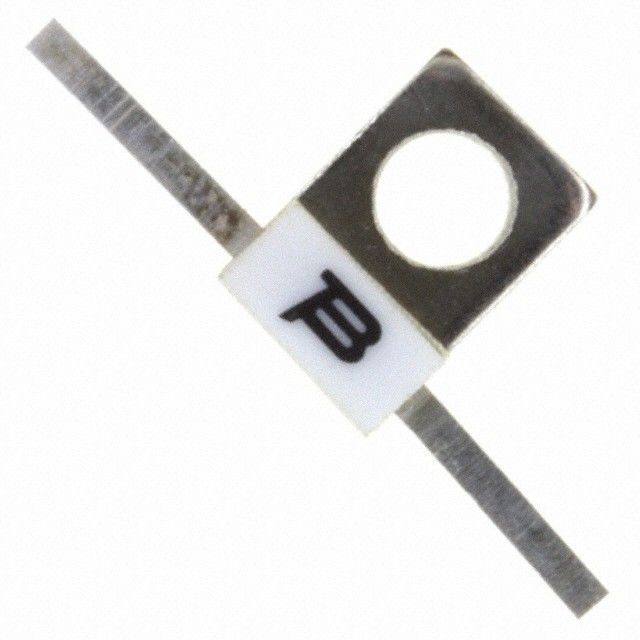

| Package Size Specs | 1.496" L x 0.980" W (38.00mm x 24.90mm) | |

| Maximum Mounted Height | 0.472" (12.00mm) | |

| Wire Lead Configuration | M4 Threaded | |

| Component Housing Style | SOT-227-2 | |

| Reliability Failure Metric | - | |

| Quality Grade Level | Automotive | |

| Certification Qualification | AEC-Q200 |

Description

The housing features a protective coating type rated Epoxy Coated. Crafted from a material mixture described as Thick Film. Furnished with features classified as Non-Inductive. Rated as Automotive grade for quality assurance. Maximum seated height of 0.472" (12.00mm) for components mounted on the board. Set up with M4 Threaded lead style for dependable connectivity. Mounting feature Flanges for straightforward installation. Operating temperature -55°C ~ 155°C for thermal stability. Enclosure Tray for component protection or transport. Enclosure/case SOT-227-2 providing mechanical and thermal shielding. Power measured in watts 200W for operational capability. Product condition Active for availability and lifecycle. Certification AEC-Q200 for compliance or testing purposes. Resistance value 100 mOhms for electrical efficiency. Product or component classification series HXP. Dimensions 1.496" L x 0.980" W (38.00mm x 24.90mm) for mechanical or electrical components. Dimension measurement 1.496" L x 0.980" W (38.00mm x 24.90mm) for component details. Coefficient of temperature ±500ppm/°C for stability in performance. Tolerance ±5% for precision in manufacturing.